If you are looking for more storage space for grain or fertiliser, you may be wondering, what are the best options available? There are many storage options available, from silos to bunkers, however, these options are single-use and they often sit empty and unused in the off-season.

This means that a storage shed is a good option as it can be used year-round, providing a better return on your investment. In this article, we look at the best sheds for grain or fertiliser storage.

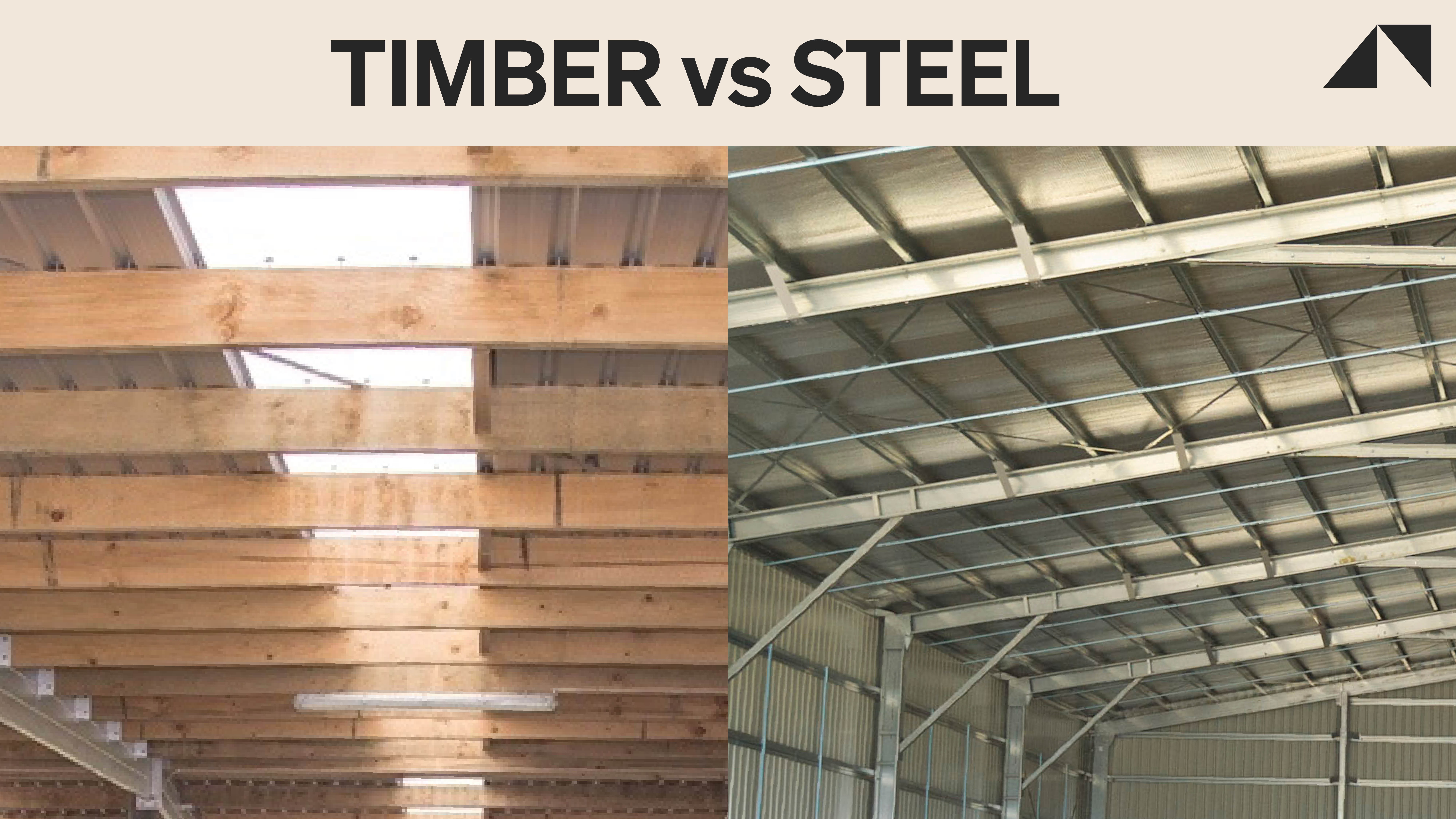

Timber vs Steel

Depending on the type of grain stored, a cubic meter can often weigh up to 700kg per cubic meter, while fertiliser can often reach 1200kg per cubic meter. Storing these products in bulk can put a lot of pressure on the shed structure, especially if the product is stacked against walls.

This means that it is important to choose the right structure so it can withstand the weight of the grain or fertiliser stored inside. Structural steel is very good for this, however, it is the most expensive by a considerable margin. The next best option is timber poles, these are very strong, especially when the diameter of the pole is increased. Poles are significantly more cost-effective than structural steel and are most commonly used.

Rollform steel sheds are common in New Zealand however this system doesn’t work so well for grain or fertiliser storage. Rolled steel is only 2-3mm thick and relies on the shape of the profile for strength rather than the thickness of the steel. As soon as the profile shape is altered, the profile loses its strength which can result in structural flaws. The lightweight nature of this product means that grain or fertiliser cannot be piled up against the shed walls as the portals are unable to withstand the weight.

In addition to this, many compounds found in fertilisers are often highly corrosive, which means that fertiliser dust will quickly corrode steel. Rollform steel is more at risk of corroding as it is so thin.

Concrete Walls and Ply Lining

Concrete walls are a must-have if you intend to store grain or fertiliser in bulk and load your shed to capacity. They will stop the weight of the product from damaging any cladding and will give you a solid wall for a loader bucket to scrape up any remaining product.

Depending on the quantity of product you intend to store, the concrete walls may need to be as high as 3.0m. This is achievable, however, concrete tilt slabs are costly and they can be difficult to engineer, especially when the concrete wall is located between the poles as it puts additional loading pressure on the shed structure. An easier and more cost-effective method is to pour a 1.5m high concrete wall between the poles and then use plywood lining above the concrete wall to help eliminate wind drift of product within the shed.

This minimises the cost, provides a solid barrier for the loader bucket, and puts minimal loading pressure on the shed structure. The plywood lining means the shed can be loaded with product which maximises storage space and minimises storage cost.

Grain and fertiliser storage is a necessary but costly exercise, no matter what system you choose. To maximise the return on your investment, consider options that can be used in the off-season. Initially, a shed will be more costly than a silo, however, a shed will provide many more uses when grain and fertiliser is not being stored.

It pays to put some thought into the shed design, how much product it will need to store, and how the shed will be used to determine what will be best for your needs. Talk to the team at Alpine, they have a lot of experience with grain and fertiliser storage, along with concrete wall designs. They will help you determine how much storage space you need, and what design is best for your individual needs.