When comparing shed options, it’s easy to focus on price and size—but what about the features you don’t want? Many cheaper sheds include design elements that seem standard but can lead to frustration, maintenance headaches, or a shorter lifespan.

When comparing shed options, it’s easy to focus on price and size—but what about the features you don’t want? Many cheaper sheds include design elements that seem standard but can lead to frustration, maintenance headaches, or a shorter lifespan.

The problem is, unless you’ve owned a shed before, you might not realise which features will cause issues down the track. That’s why we’re highlighting some of the most common shed features to avoid—so you can make an informed decision and invest in a shed that’s built for the long haul.

CLICK TO READ:

Specific features to Avoid:

- Non-Birdproof Design

- Apex and Knee Braces

- Lack of Proper Rust Protection

- Tek Screw Connections

- Complicated Structural Floors

A Non-Birdproof Design

One of the most overlooked issues in shed design is birdproofing. It might not seem like a big deal at first, but once birds find their way inside, they can cause major headaches—leaving droppings, building nests, and even damaging stored equipment.

Many cheaper shed designs use C-section purlins in the roof which makes for a perfect nesting place, and therefore a prime target for birds. Anything stored in the shed below quickly gets covered in acidic bird droppings which leads to significant damage and an unhygienic working environment.

Always look for a shed design with enclosed purlins and rafters, also make sure the purlins sit between the rafters and not on top, as this will provide more nesting places.

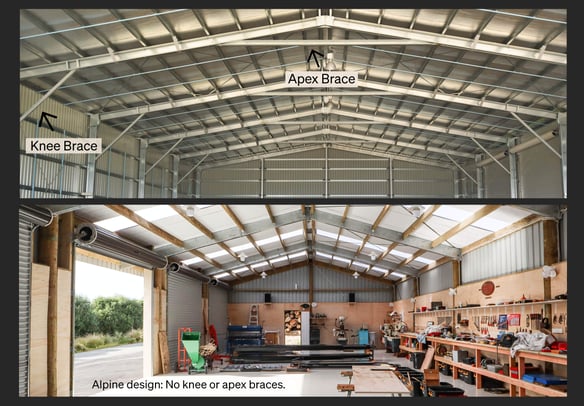

Apex and Knee Braces

Apex and knee braces are often used in cheaper sheds to provide extra support where framing is weak. While they may seem like a practical addition, they come with two major downsides:

- They create the perfect nesting spots for birds. These braces form small, sheltered spaces that birds love to nest in, leading to mess and maintenance issues.

- They reduce your usable internal space. Apex braces cut into your headroom, while knee braces take up space along the walls—limiting storage options and making it harder to move equipment around.

Apex and knee braces are often sold to the potential client as a positive design feature because they add strength to the building. While this is true, they are only required because the rest of the materials used in the design are not strong enough to stand without them.

Some shed designs, like the Alpine system, use timber poles and thick structural steel—eliminating the need for apex and knee braces. With materials this strong, extra bracing simply isn’t necessary.

Lack of Proper Rust Protection

Rust is one of the biggest threats to the lifespan of a shed, especially in New Zealand’s harsh and varied climate. Yet, many cheaper sheds use roll form steel which is only 2-3mm thick. This steel cannot be hot dip galvanised as it cannot withstand the heat of the galvanising baths, therefore it only has a thin layer of electroplating protection which wears off over time. This leaves the steel vulnerable to corrosion, structural weakening, and costly repairs.

If you are looking for a shed that will stand the test of time, 5-10mm thick hot-dipped galvanised structural steel is a much more durable option, and while it costs more upfront, it will last more than twice as long.

Tek Screw Connections

Many roll-form steel sheds rely on tek screws for assembly because they are a cheaper option, however they create serious long-term issues - particularly in strength, durability, and rust resistance.

Unlike bolted connections, which securely clamp materials together, tek screws are self-tapping and are simply screwed through 2-3mm thick steel. This presents two major problems:

- Rust Formation – The installation process generates heat and friction, which burns off the electroplating rust protection, exposing raw steel to the elements. Over time, rust forms around the screw, weakening the connection point.

- Structural Weakness – Since the screw is only held in place by thin steel, it acts as a pivot point. As rust sets in and weakens the connection, the screw begins to wiggle loose, creating rattles, movement, and structural instability.

Complicated Structural Floors

One hidden cost of cheap kitset sheds, especially those made from roll-form steel, is that they require a structural concrete floor. Since these sheds rely on the slab for stability, the floor must be heavily reinforced, often requiring perimeter thickening and extra steel reinforcing. This makes installation more labour-intensive and significantly more expensive.

In contrast, timber pole sheds don’t need a structural floor because the poles are concreted into the ground, providing natural stability. This means you can opt for a non-structural concrete floor, which is more cost-effective and simpler to install.

Cost Difference

A structural concrete floor typically costs around 25% more than a non-structural floor due to:

- Extra reinforcing steel

- Perimeter thickening

- More complex preparation and labour

This means that while a cheap kitset shed might look affordable upfront, installation costs can add up quickly—often making it more expensive than a high-quality pole shed with a non-structural floor.

Alpine pole sheds are designed to work with cost-effective, non-structural floors, giving you a strong, durable shed without unnecessary expenses.

A Shed That’s Built to Last

Not all sheds are created equal, and while some design features might seem standard, they can lead to unexpected costs, maintenance issues, and long-term frustration. From bird nesting spots and rust-prone tek screws to complicated structural floors, the wrong choices can turn a seemingly affordable shed into an expensive headache.

By avoiding these common shed features, you can invest in a practical, durable, and hassle-free shed that meets your needs now and for years to come. Alpine sheds are designed with strength, simplicity, and longevity in mind, so you get a shed that works for you—not against you.

If you're looking for a shed that’s built for the long haul, get in touch with Alpine today. Our team is here to help you find the best solution for your property, budget, and long-term goals.